Counterbalance Electric Truck Daily Checklist

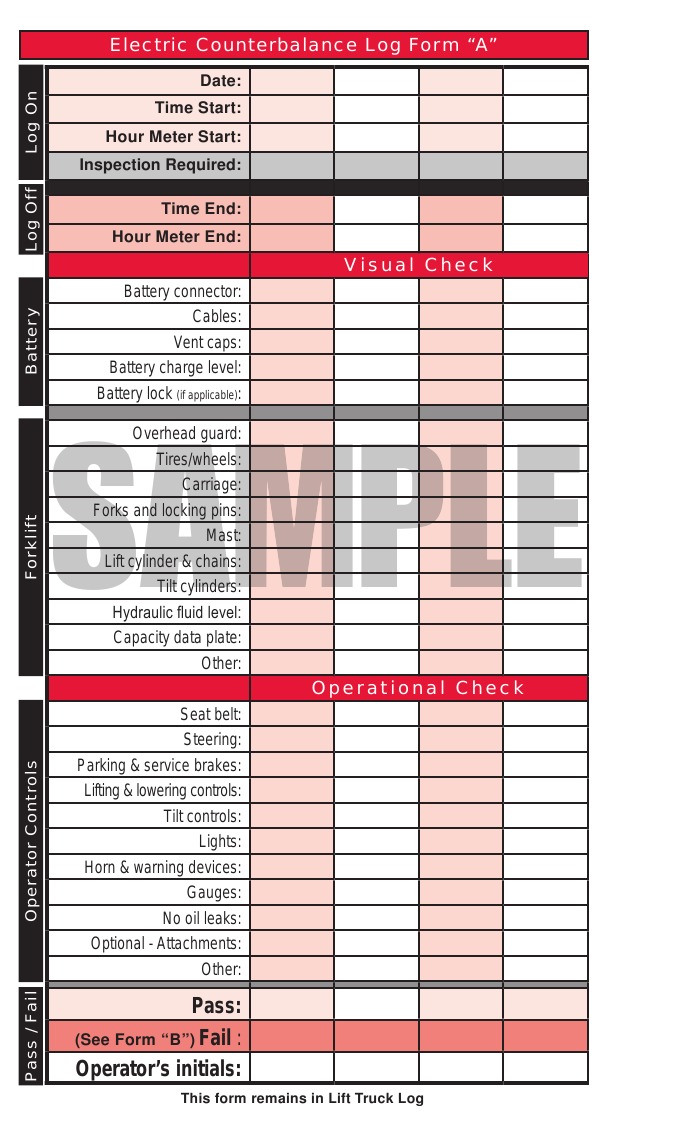

Ensure the battery area is clean and clear from debris.

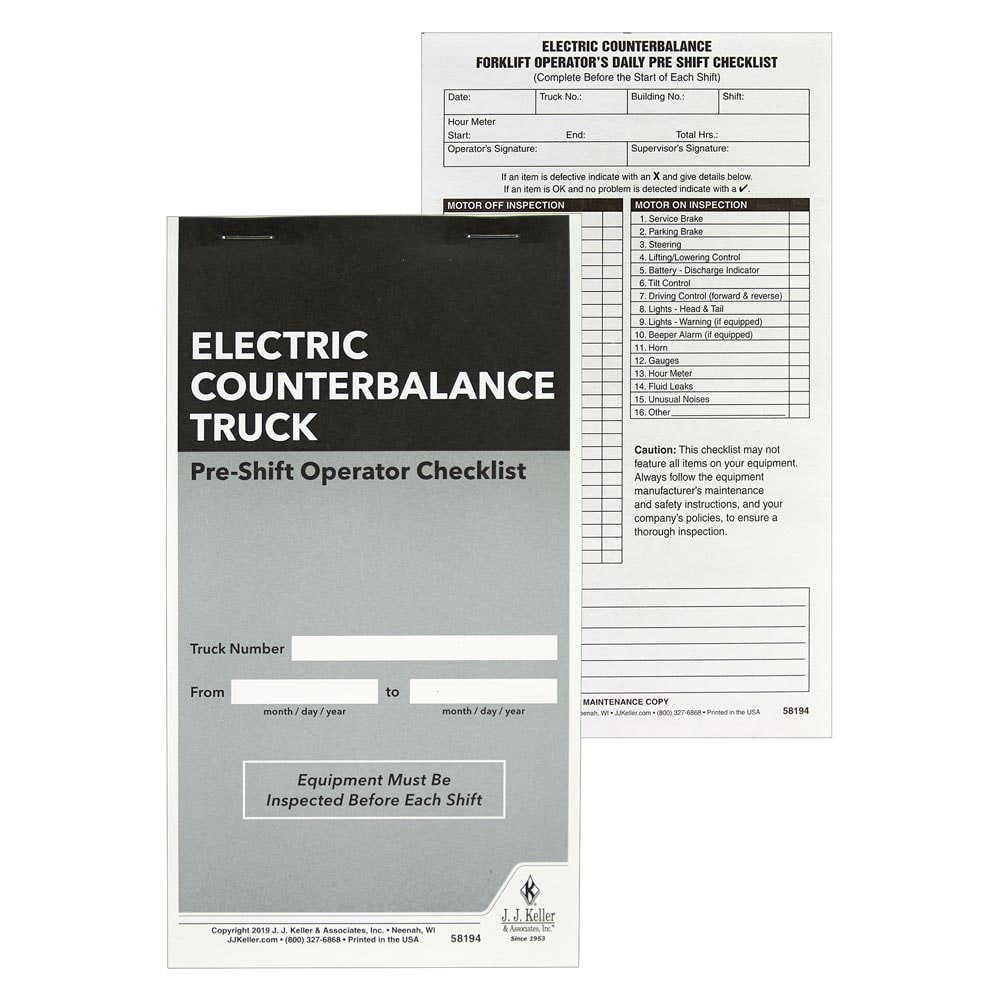

Counterbalance electric truck daily checklist. Damaged bodywork may indicate other problem areas on the truck. Check all for correct operation. Daily operator checklist for use with electric counterbalance 7 in height 4 1 2 in width. Safety guards and covers.

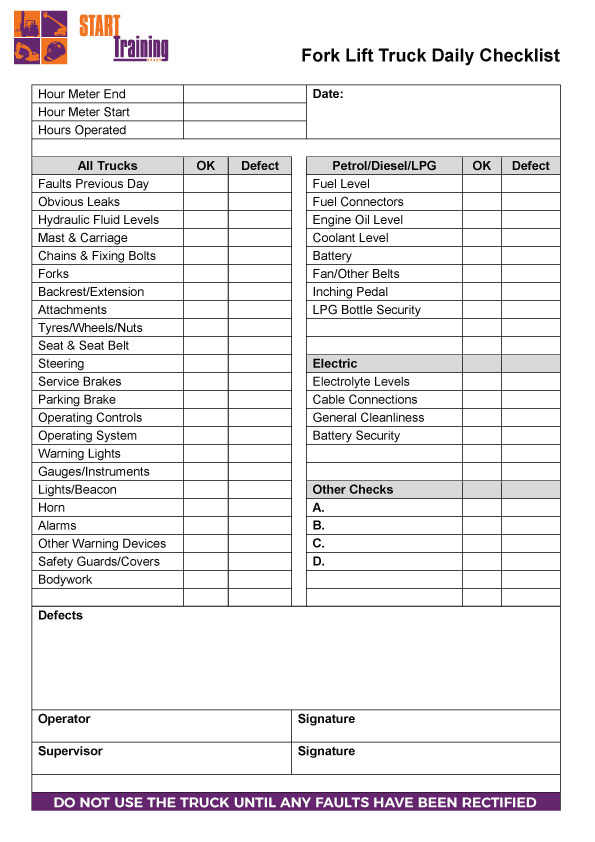

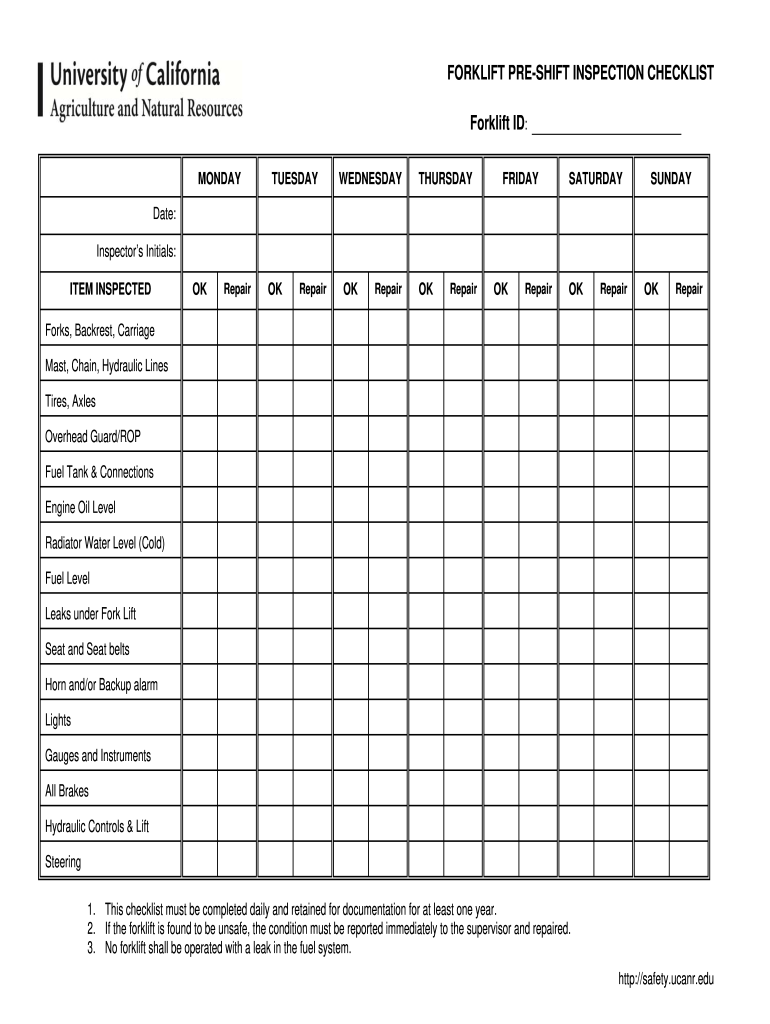

Check the areas carefully. 1 before starting the engine and 2 after starting the engine. Check tire condition pressure and look for any cuts or gouges. Counterbalanced forklift pre use inspection checklist operator.

Check they are clean and properly secure. You will always have the right truck. Visually check around the vehicle. Use this checklist to identify where a problem is detected or if there are not problems visible.

Check functionality of finger guards. A forklift daily checklist is used prior to the daily operation of a forklift to ensure that it is in good working condition. Ensure the batteries are secure within their compartment and that any protective hatches are properly closed. Ensure load backrest extension functions properly.

Check the electrolyte levels of all cells. Electric truck daily checklist english. This forklift daily inspection checklist is divided into two parts. Determine fork condition remembering to check the top clip retaining pin and heel.

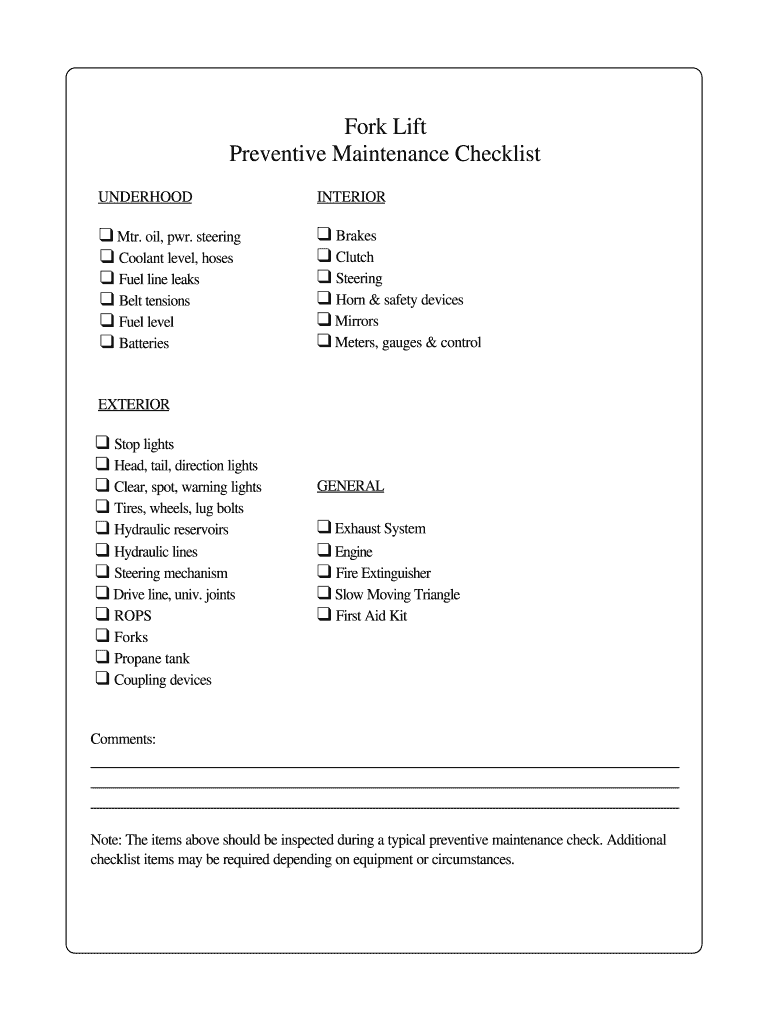

The unicarriers electric counterbalance trucks are designed to secure your productivity all the way every day. Narrow aisle lift truck checklist english. Power off checks status ok no n a power on checks status ok no n a 1 wheels and tires m m m 18 unit starts and runs properly m m m 2 lights strobes m m m 19 instruments gauges m m m. A flapping cover can be a hazard to your colleagues as well as yourself.

Department of labor s. To zoom in use the keyboard to focus on the arrow icon within the product image. Check all are properly fastened and secured. They are not a substitute for any of the provisions of the occupational safety and health act of 1970 or for any standards issued by the u s.

These tough multifunctional problem solvers range from 1 25 to 3 5 tonnes and include innovative features to meet the highest demands on effi ciency durability and ergonomics. Use this checklist to identify where a problem is detected or if there are not problems visible. Ensure safety decals and nameplates are legible and match the forklift model.