Corrugated Aluminum Sheet Environmental Impact

A horizontal crack in the aluminum face sheet also began to form and eventually linked the side and central vertical cracks allowing a flap of face sheet to open near the end of the ballistic event.

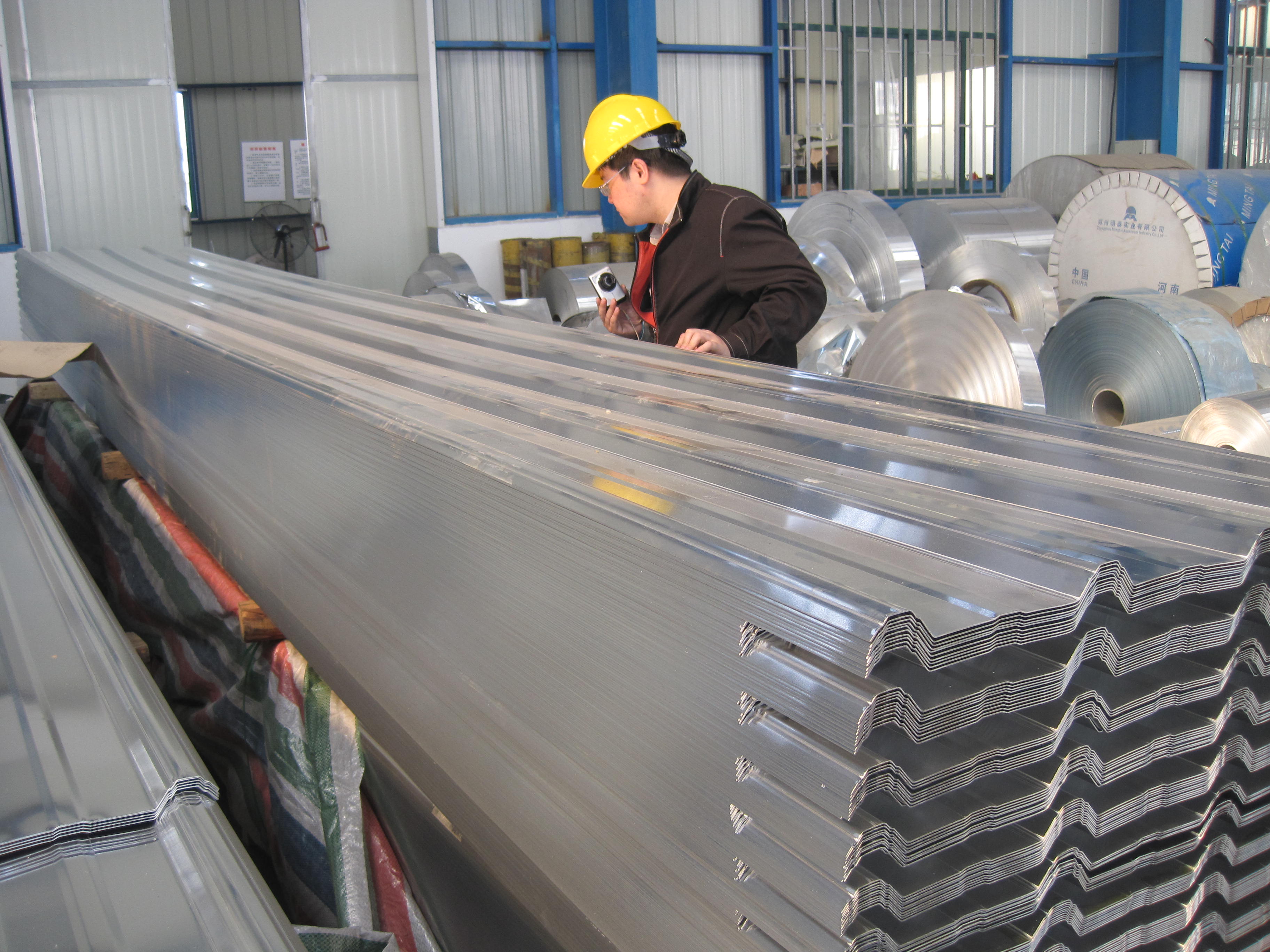

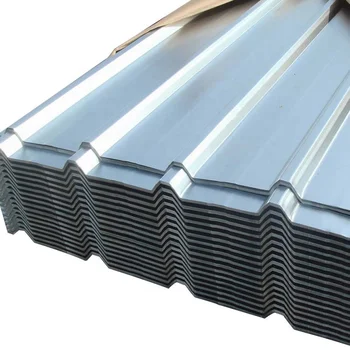

Corrugated aluminum sheet environmental impact. Focus guest chair part 3. Corrugated sheet metal is a tough material light weight weather resistant and practical for many different uses. These corrugated panels are made of rippled metal sheets one of the most commonly used panels in the industry. Fences privacy screens siding roofing and more.

As a thin planar material corrugated metal can be used for many flat applications. Corrugated metal sheet is a tough light weight and weather resistant material that provides advanced protection qualities that cannot be matched by any other type of material. Because of the special corrugated shape flimsy and lightweight metals like aluminium can also be equipped to undergo decades of weather beating. Due to its innate high grade quality metal corrugated panels are extremely resilient manufacturing materials that provide numerous benefits to a wide range of.

Lightweight and flexible these decorative low rise corrugated aluminium sheets are available from stock in a selection of perforated and un perforated patterns. What makes us special is that we are an integrated manufacturer from raw material to finished product at one facility. The new study builds on the first ever u s. These finely formed corrugated panels are primarily used for cladding applications within the interiors market including exhibitions leisure office and retail sectors.

Corrugated metal panels are available at local hardware stores but professional contractors have access to a wider range of corrugated sheet metal in varying thicknesses from wholesale suppliers. Corrugated aluminium cladding panels. We handle large scale recycling of occ old corrugated containers in our recycle waste products division. Greenguard certification laboratory atlanta georgia compound criteria acceptable a polyethylene bag covers the chair and is placed in a corrugated cardboard carton.

As per the pollution levels prevailing where they are installed corrugated sheets have to be maintained every 5 10 years. Corrugated sheeting can also be overlapped which often avoids the need for reducing the lengths by cutting. The corrugated industry released its third life cycle assessment report in june 2017 measuring and documenting the cradle to cradle environmental impact of corrugated packaging manufactured in 2014. Environmental data sheet for chairs part 1.

At about 160 μs after impact white debris began to be emitted from the crack on the left at a shallow angle to the back face surface normal. Manufacturing process description test location.